Millie went to see the Bennamann research facility based in Cornwall to look at how this research is progressing, and whether it is something our clients should be investing in.

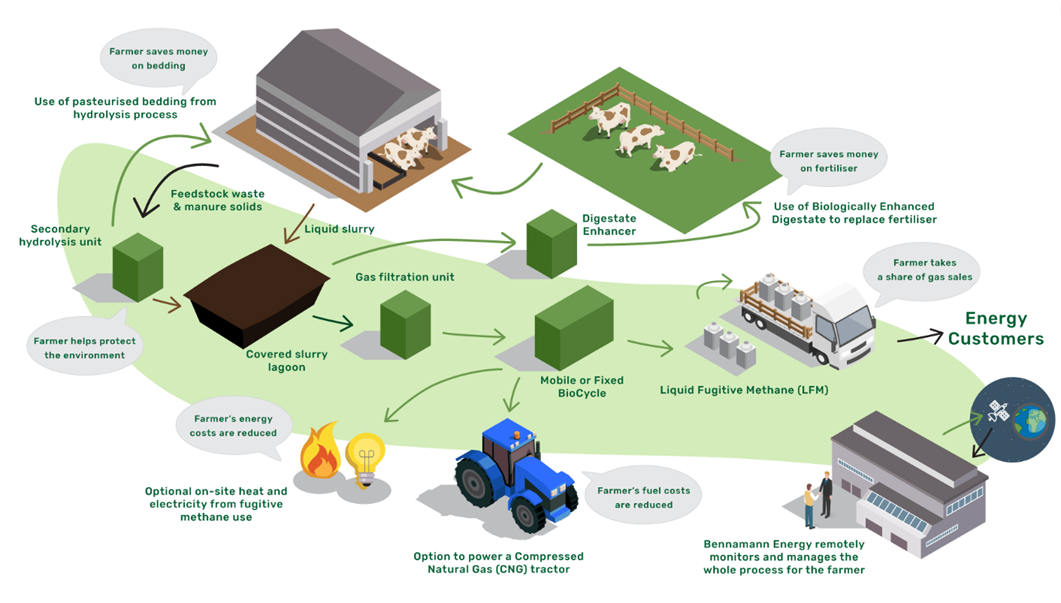

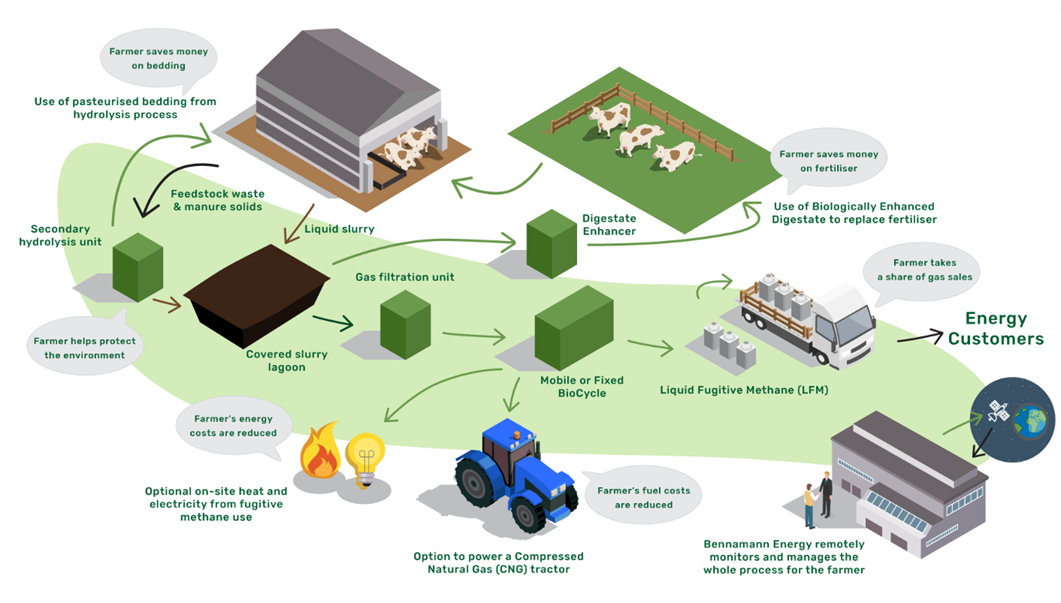

Bennamann Ltd is at the forefront of the research, development, engineering and manufacturing in all four stages of the fugitive methane value chain, which include capture and process, storage, distribution, and use. They have recently partnered with CNH industrial, who have driven innovation in developing alternative methane fuelled powered machinery.

The process starts with the Bennamann smart cover, which are a modular cover that can be adapted to most slurry storage facilities. These are eligible for the Slurry Infrastructure Grant funding. The smart covers collect ammonia released from the store and transfer them to a filtration facility.

The biogas produced can be filtered to remove the abrasive and harmful gasses, and the resulting methane is then used to run a generator or methane powered tractor.

The methane can be stored and transported in patented fuel tanks.

If used on farm, it costs (in fuel equivalent) 18ppl, which can be a significant saving from the rise in fuel prices we have seen over the last few years. However, this fuel can also be sold back to Bennamann.

They have developed their system to be modular so investment can be staged, and the amount of methane harvested will impact the potential return It claims to work in a variety of systems, from extensive grazing systems, whose slurry store is mostly parlour washings, to sand based fully housed system. The return on investment is one if the main differences between the different system set up, with the quantity of slurry collected is reduced on an extensive grazing-based system.

Figure 1: Business and operational model for slurry manure based farm customers.

Reference https://bennamann.com/bennamann-energy-ltd/

The main benefits for the farm:

- Reduces C02 emissions significantly

- Operational cost savings on electricity, diesel and fertiliser

- Soil regeneration, with improvements to the grass yields and worm density counts

- Reduces quantity of carbon produced on farm on a per litre basis.

This system offers a potential income source, potential reduction in fuel and fertiliser cost and reduction in cost risk to a livestock business for example, energy and fuel price rises.

However, there are costs associated with investing into this system, including the service package that would be needed and there are no indicators of the price you would receive for the fuel sold back to Bennamann which is a significant proportion of the cost-benefit analysis of the system. Bennamann claims to have a 5-year return on investment net of grant and will talk to farmers on an individual basis regarding cost of set up, service package and cost of harvesting the methane.

Would the Bennamann System work for you?

If you want to talk through this system please get in touch.